A digital upgrade for fish processing machines

Sustainable production, savings on repairs and spare parts and better-quality end products.

When it comes to our customers, it is not just about keeping their production going – focusing on how we can help them make production easier, less expensive and above all, sustainable, is equally important. Digitisation is part of the solution.

At Petur Larsen, we can now provide a thoroughly tested digital solution, which can be installed in most fish processing machines.

Some of the benefits of Intelligence Kit

Sustainable production

Producers in the fishing industry must meet increasingly stringent requirements in relation to environmental certification and reducing their water and electricity consumption.

Every operator must optimise production and reduce and register their consumption of energy and water before the fish reaches the dealer. These requirements apply to our customers all over the world. Digitisation is part of the solution.

With Intelligence Kit installed, you can monitor water and energy consumption. You can regulate the individual machine’s water consumption so that it is kept to a minimum and electricity consumption is regulated by automatically stopping the machine when there are no fish in it. The automatic setting of e.g. wash programmes, means that every single stage in the process is optimised with as little energy consumption as possible. Waste is reduced – without it costing extra resources in production.

Reduce repairs and spare parts costs

Production stoppages, repairs and wear on spare parts are a considerable cost factor when it comes to food production.

Sustainability is therefore not just a parameter in relation to energy consumption, it is equally important in helping to reduce costs in relation to man hours and spare parts. At Petur Larsen, we have focused on this for many years. Our Intelligence Kit means that we can now provide a solution that allows you to automatically finely adjust machines and production to such a degree that there is less maintenance, less wear and fewer production stoppages. The machines stop when there are no fish on the conveyor and for example, you can set the use of the individual knives separately in the machines, which do not need to operate during cleaning. This increases the lifetime of all parts because they are never used unnecessarily.

Fewer faults and fewer unforeseen production stoppages

Intelligence Kit provides constant real-time monitoring of the machine’s functions

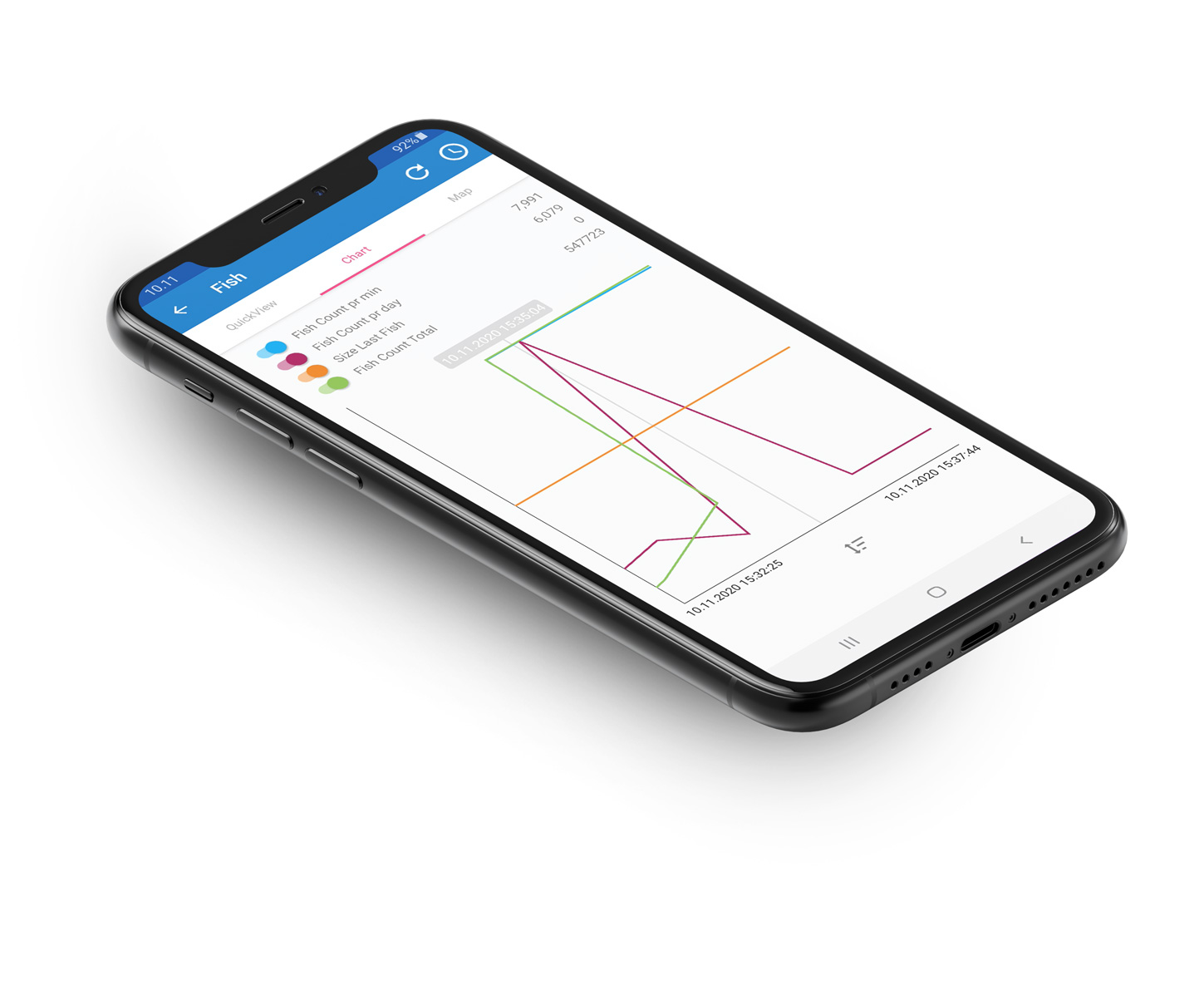

Intelligence Kit provides smartphone access, immediately providing a warning if there are production irregularities. It means you can take action immediately to minimise the problem. Fault rates decrease and efficiency improves. In addition, every single production stoppage is registered and the data saved so that you have an ongoing overview of the operating status of every single machine. Intelligence Kit monitors and controls several machines throughout the entire processing operation, from the supply of water to the conveyor belt.

Overview of costs and quality

With ongoing registration and measurement of fish size, a fish counter and saddle counter, all of the information about the product’s quality is accessible in real time on a dashboard.

The dashboard is designed for ease of use and can be accessed via a smartphone. You can constantly monitor information about fish size in relation to energy and water consumption. This means that you gain a qualified overview of the quality of the individual fish and production costs for every batch – the best way to gain an overview and to set the right price, so there is profit once all of the costs have been calculated.

Dashboard and smartphone control

Digitisation usually arrives in complex versions that require a lot of effort from the individual employees just to use it – but not with Intelligence Kit.

Our platform is based on the principle that it must be easy to use. With an app that is simple to use, all information and control can be managed directly from a local dashboard on a smartphone.

Follow production in real time. You will receive an alarm and notification of any production stoppages, water wastage or faults in the filleting process. A digital upgrade of your machines means fewer faults. Intelligence Kit provides smartphone access, immediately providing you with a warning if there are production irregularities.

As alarm activates automatically when water consumption or power consumption is too high.

Can Intelligence Kit be used on all machines?

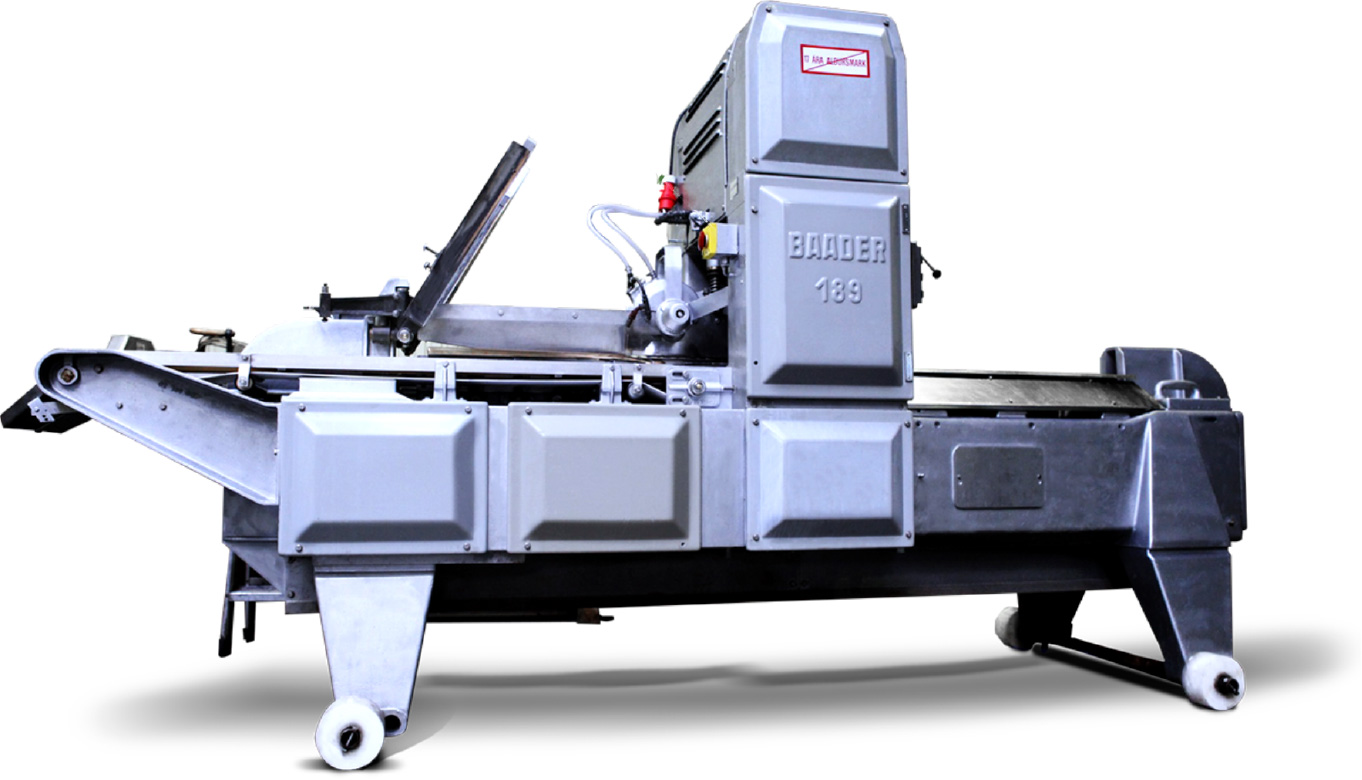

Traditional fish processing machines are simple and mechanical, made from strong materials and have a long lifetime. With Intelligence Kit installed, you can give your machines a digital upgrade.

Our experts at Petur Larsen have developed Intelligence Kit in collaboration with our customers. It is adapted so that it can function with most machines that operate in most production setups.

At Petur Larsen, it is crucial that everything we develop is created so that it can be implemented and with just a few adjustments be used in existing production setups.

Thoroughly tested and already in use

In a collaboration with Schneider Electrics and selected customers, Petur Larsen developed Intelligence Kit in 2018. More than 600 hours of development time has been spent on its creation and the aim was to create a digital optimisation of well-functioning mechanical quality machines that are already installed in production setups at our customers’ production sites.

Petur Larsen is well-known for being physically present at its customers’ production locations all over the world. The company’s technicians and experts operate on the production floor and they know the production conditions at individual customers’ production sites. This is why Petur Larsen has a tradition for working in collaboration with fish producers to develop new solutions that can be installed and used in existing machines.

Intelligence Kit is already installed at local customers’ production sites in the Faroe Islands, and several locations around the world are preparing to use Intelligence Kit.

Ready to get digital?

Our experts are ready to help you find out how you can digitise your BAADER machines.